Wire / Cable Crimping Service

Wire Crimping

Wire / Cable crimping by YU TAI utilizes a new type of terminal crimping with pressure detection system, which is specially designed to crimp wires and cables with both single and double crimping. The quality of wires must be carefully verified and ensured when we are crimping them. YU TAI uses fully automatic technology to ensure the quality of its processing. Our 12 servo automatic terminal crimping machines can handle urgent orders, and we also accept international orders.

Professional Team

YU TAI is an ISO-certified manufacturer that offers crimping services in compliance with IPC regulations. We have professional capabilities. To cooperate with us when you need wire/cable assembly or harness processing, you can send us pictures or use the inquiry button above.

The cable/wire and electromechanical component crimping services are all handled by engineers with certain expertise. The products of cable assembly and cable harness are all not in stock, all customized. We manufacture and test all our cables in accordance with international standards, which can meet specific industry needs.

If you want to learn more about our capabilities or discuss services such as crimping cables, wire harnesses, and electromechanical assembly. You can contact us for a quotation.

The Process of Cable / Wire Crimping

The process of cable / wire crimping refers to the interaction between terminals, wires cables, machines, personnel, methods, procedures, and environmental attributes. Only by controlling the manufacturing process that can be produced high-quality crimp products. The terminal tension test is based on Form 19-12 of 19.7.2.1 in the IPC specification as the requirements and acceptance. Stripping inner Core is based on 3.2 and 3-1 in the IPC specification as the requirements and acceptance. Crimping terminals is based on 5.1 in the IPC specification as the requirements and acceptance.

The Process is as Following

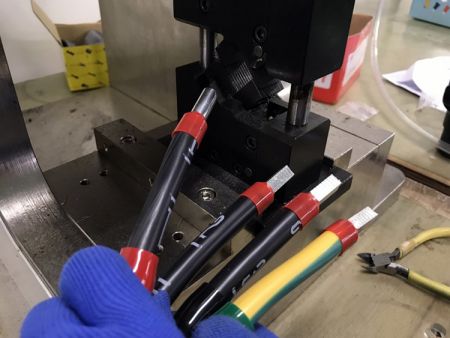

1. We use special crimping tools for processing to ensure that the product does not have poor contact or disconnection.

2. We do confirm the scope of use of our customer's wires/cables, and before processing, will first ensure that the product is suitable for crimping, such as whether the wire diameter and the mating terminal meet the specifications.

3. Before making cable crimping, we will confirm the stripping length follow the IPC specifications, and judge whether it meets the specifications according to the type of cable/wire, crimping method and results.

4. We will check out our final products also by Visual inspection, pull test and use metallographic analysis to confirm the condition of the product after the cable crimping.

- Gallery