Quality Policy

Over 40 years of experience in custom cable assemblies and cable harnesses, certified with ISO 9001/IPC

YU TAI emphasizes cable product quality improvement; we had obtained ISO 9001 international certification in 2015 and RoHS compliant. To introduce the international cable harness-processing standard, we had joined the IPC member in 2018. For providing you with more stable and high quality, we had trained our employees to obtain the IPC (Certified IPC Trainer) certification for cable harness processing and trained 10 employees to obtain the CIS (IPC specialist) certification. We have been committed to the development of high-technology customers, such as wafer equipments, panel equipments, automation equipments, in addition to investing in more stable production equipments, we also invest in inspection equipments which meets customer needs.

Quality First: No defective products are produced, Not out of bad products.

Suppliers Control

Based on the cooperation experiences with suppliers, select excellent suppliers to maintain the quality of parts and the stability of delivery

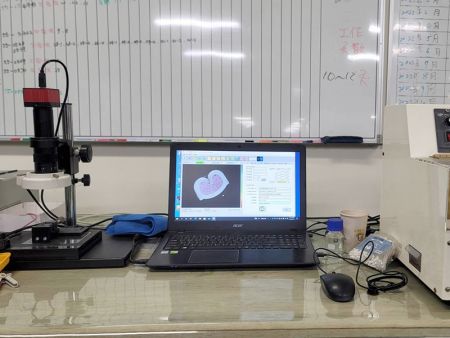

Manufacturing Process Quality Control

Use professional equipments to produce, maintain stable quality, and confirm the quality of the work, such as tension, to confirm whether the tension meets the IPC standard.

Final Inspection

Perform appearance inspection according to customer requirements or IPC standards, and use wire / cable testing machine, use customized test fixture, 100% test whether the electrical characteristics meets the specifications, such as HIPOT TEST, insulation, conducting test, etc.

Quality Control Inspection

The quality control personnel conduct inspections in accordance with the MIS1916, and strictly implement 0 acceptance and 1 return for quality control. The inspection items are appearance, size, assembly, and electrical characteristics.

Abnormal Control and Recurrence Prevention

For exception handling, professionals will conduct exception analysis, systematically formulate recurrence prevention countermeasures, and track the improvement effect with the client.

Quality Inspection

- Tensile Testing Machine.

- Metallurgical Analysis Apparatus.

- Universal Material Testing Machine.

- Cable Testing Machine.

- Download