Factory Introduction

YU TAI provides professional cable assembly and harness services to accelerate production line automation

With well-stocked cables and wires, we have relationships with suppliers throughout the world, stable factory management to provide on-time delivery is vital because cables come in a wide variety of specifications. Our management concepts are professional, quality and efficiency, and we are committed to the rationalization, standardization, and automation of production operations, and comprehensively improve efficiency and quality, and have professional technology. To produce the highest quality products to satisfy our customers and make overall quality and efficiency are improved. In addition to the continuous improvement of systems and equipments, we are also committed to cultivating professional talents, with professional technology and management teams, improving various customer service capabilities, and gradually advancing toward smart factories with the goal of industrial e-commerce.

The Principles and Methods of Factory Management

1. Establish an assembly line: Subdivide the assembly work into multiple simple actions, and then set up an assembly line to connect simple actions. The workers will be more skilled and more efficient with the simple actions. Set up assembly production lines to connect simple actions to make production smoother.

2. Establish working standards and formulate standard working hours: Working standards can shorten the time for employee education and training, and make operations more proficient and more efficient in production. Standard working hours can be used as the basis for performance appraisal, as well as for production planning and human resource arrangement.

3. Use the appropriate tools to find the best method: Design suitable work desks, work chairs and tools to make the operation simple, easy to be proficient, and increase efficiency.

4. We continuously introduce and update advanced production and inspection equipments, and we have professional technology to produce the best quality products to satisfy our customers.

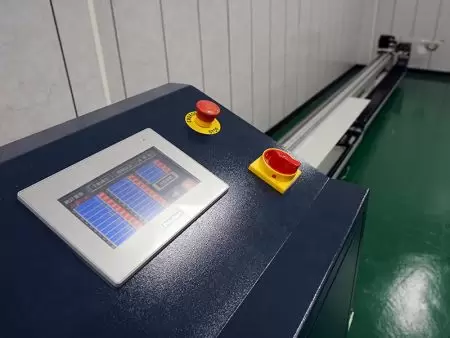

Our Automation Equipment

| Automatic Tensile Testing Machine | Tensile testing (under 50KG) |

| Automatic Soldering Machine | The temperature and the amount of tin output can be adjusted, and the foot switch automatically discharges the tin to increase work efficiency |

| Automatic Terminal Crimping Machine | Applicable to differernt type of terminals, Y type terminals, Insalution terminals, and can quickly change the mold |

| Injection Molding Machine | Connector protection shell, injection molding |

| Cable/Harness Tester | End-point test of all kinds of wires/cables, connectors, wire & cable and connector combinations; test various of wires, connectors, and the combined products of connectors and wires. |

| Cross Section Analyzer | Cut, grind, corrode and clean the terminals, collect cross-sectional images, and measure and analyze the wiring harness terminal pictures |

| Cable Cutting & Stripping Machine with Wire Take-Up Device | Strip outer sheath and inner core sheath of multi-conductor cables simultaneously. wire cutting and stripping + cylinder manipulator + wire take-up device |

| Nylon Power Distribution Pipe Cutting Machine | Cut nylon power distribution pipes with high cutting accuracy |

| Wiring Harness Heat Shrinkable Tube Heating Machine | It features double-sided heating, which can heat the shrinkable tube evenly. The heating temperature, conveying speed, and heating zone width are adjustable. |

| Rotary Air Stripping Machine | Rotary knife pneumatic wire stripping machine is mainly used to strip large cables, the maximum wire diameter is 50 mm, the maximum stripping length is 100 mm |

| Automatic Cable Cutting Stripping Machine | Cutting the cable and stripping the outer sheath at the same time |

| Automatic Cable Cutting Machine | Cutting the cable and stripping the outer sheath at the same time, and with twisting function |

| Pneumatic Stripping Machine | stripping the outer sheath of cables |

| Server Motor Semi-Automatic Terminal Crimping Stripping Machine | The host engine is driven by a servo motor, and the stripping part is driven by a stepping motor, so that the wire stripping and terminal crimping can be completed at the same time |

| Pneumatic Crimping Pliers | The crimping tool adopts a curved propulsion mechanism, the applied force is transmitted to the four indenters through the four curves in the cavity of the right pliers handle, the precision ratchet ensures the consistency of the indentation and the crimping quality of the wires and contacts |

| 2-Component Dispensers | 2-component mixers, precision measurement, according to the characteristics of the rubber material, it can be configured with functions such as pipe heating, tank heating, vacuum stirring and defoaming. For all kinds of two-component AB glue applications such as silicone infusion, epoxy resin dispensing, PU glue encapsulation. |

| Universal Testing Machine | Tensile testing (under 50KG) |

| Pneumatic Stripping Machine | stripping the outer sheath |

| Hydraulic Crimping Terminal Machine | Used for crimping various terminals for large square cables, the mold can be replaced with hexagonal crimping, the maximum crimping size is 500mm square |

| Automatic Pressure Detection Crimping Terminal Machine | It is connected to the semi-automatic crimping terminal machine and the automatic cutting and crimping machine, and the detection data is set by the interface. Crimping pressure is detected by the force transmitter and the pressure curve and pressure value are displayed by the interface |

| Crawler-Type Shielded Wire Brushing Machine | Used for shielded braided layer of wire and cable, brushing and untwisting |

| Cable Bending Test Machine | Wire bending durability test |

Gallery

- Cable Cutting and Stripping.

- Crimp Connection.

- Welding.

- Baking Heat Shrink Tube.

- Wire Bending Durability Test.

- Cutting the cable and stripping the outer sheath at the same time, and with twisting function.

- End-point test of all kinds of wires/cables, connectors, wire & cable and connector combinations; test various of wires, connectors, and the combined products of connectors and wires.