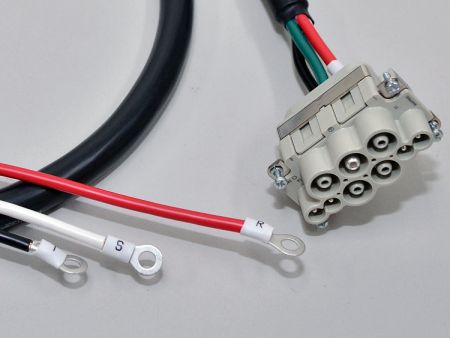

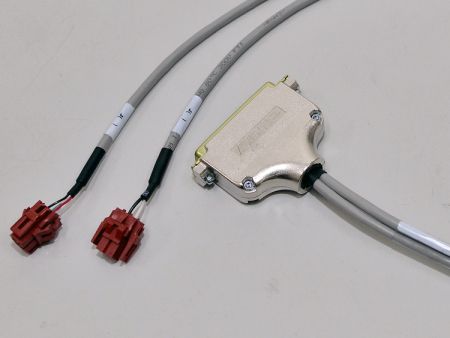

Cable Assembly and Cable Harness of Machine Tool

TE Connectivity, HARTING, Amphenol, Molex.

Cable Assembly & Wire Harness Manufacturing

YU TAI can produce Cable Assembly and Cable Harness for Machine tool. Machine tool is the mother of machinery, as a benchmark for evaluating a country's industrial competitiveness. In the processing of cable assembly and cable harness, YU TAI knows deeply that the quality of cable assembly and cable harness will have a significant impact on the operation of the machine. So that YU TAI all use the connectors of well know international factory for cable assembly and cable harness. For example, TE Connectivity, Amphenol, Molex…etc.

Our wires and cables must be with UL and RoHS Applications to ensure the stable quality.

Diversified Applications of Cable Assembly and Cable Harness

Cable assemblies and cable harness are the key parts of machine equipments. YU TAI will cooperate with you, according to the YU TAI will cooperate with you to manufacture Cable assemblies and cable harness according to your conditions and environment required by your industry, plus our understanding of wires and cables.

YU TAI will judge and consider based on our experiences, including the size, outer diameter, and length of wire and cable be suitable for what kind of manufacturing method.

Our production processes are all in accordance with RoHS and lead-free for environmental protection.

We have ISO certification, and our assembly process is in accordance with IPC international standards, and the parts and materials are complied with ROHS to ensure a safe and friendly global environment.

- Gallery